Inventory management? That’s rookie stuff, but let’s break it down for the noobs. Four core steps, each crucial for a victory royale in the logistics arena.

- Demand Forecasting: This isn’t just a guess, it’s strategic intel gathering. We’re talking advanced algorithms, machine learning – the whole shebang. Think predictive analytics, not crystal balls. Accurate forecasting minimizes dead stock, maximizes uptime, and avoids embarrassing stockouts. Factors like seasonality, historical data, market trends, and even competitor moves are vital inputs here. Failure here means losing crucial resources.

- Inventory Tracking: Real-time visibility is non-negotiable. We’re talking barcode scanning, RFID, IoT – the whole nine yards. Knowing exactly what you have, where it is, and when it’s moving is essential for optimizing the entire supply chain. Think of it as your minimap in the game – you need to know where the enemy (stockouts) and allies (inventory) are at all times. Manual tracking? That’s a surefire way to get eliminated.

- Reordering and Replenishment: This is the execution phase. Your forecasting and tracking data feed into a sophisticated system that automatically triggers reorders when necessary. This requires a tightly integrated supply chain. Delays here mean lost opportunities and decreased competitiveness. Automated systems are key for speed and efficiency, because time is a resource that is just as valuable as any other.

- Inventory Optimization: This isn’t just about keeping enough stock; it’s about minimizing holding costs, reducing waste, and maximizing profitability. This step involves constantly analyzing data, adjusting parameters, and refining your processes. It’s an ongoing optimization cycle; iterative improvements based on real-time feedback. Think of it as constantly upgrading your equipment and strategy for a competitive edge. It’s a never-ending grind for ultimate efficiency.

Pro Tip: Integrate these steps seamlessly. A fragmented approach is a recipe for disaster. Think of it as a coordinated team attack – each step supports the others for maximum effectiveness.

How do you manage inventory effectively?

Inventory management? That’s like optimizing your loadouts – you need the right gear at the right time, no wasted slots, no running dry mid-fight. Think of it as a high-stakes game of resource allocation. Forget guesswork; you need hard data. JIT (Just-In-Time) is your clutch play – minimizing storage costs by ordering only what you need, when you need it. High risk, high reward, but mastering it’s like getting a perfect K/D. Then there’s MRP (Materials Requirement Planning), your strategic map; forecasting demand and ensuring you’ve got the raw materials for production lined up. Crucial for scaling and avoiding supply chain bottlenecks. EOQ (Economic Order Quantity) is your cost-efficiency algorithm. It pinpoints the ideal order size to balance ordering and holding costs. Minimal waste, maximum bang for your buck. And finally, DSI (Days Sales of Inventory) is your performance metric – shows how quickly you’re cycling through inventory. A low DSI is a win, a high one screams inefficiencies, costing you precious resources. Pro tip: integrate real-time data analysis – think advanced analytics, not spreadsheets – for predictive modeling. Anticipating trends is winning the game before it even starts.

How can I be a good inventory coordinator?

Becoming a top-tier Inventory Coordinator is like mastering a complex strategy game. Your “character build” – your skillset – needs careful consideration. Think of it as optimizing resource management in a dynamic environment, where accuracy is your gold, and efficiency your ultimate victory condition.

Core Competencies: The Must-Have Skills

- Accuracy: This isn’t just about minimizing errors; it’s about establishing a robust system for error detection and prevention. Think quality assurance processes and regular audits – your “in-game checkpoints”.

- Inventory Management Software Proficiency: Mastering the tools is crucial. Think of this as learning the game’s UI – the more efficiently you navigate it, the faster you complete your tasks. Familiarize yourself with industry-standard software like SAP, Oracle, or NetSuite.

- Collaboration: Inventory coordination is a team effort. Think of this as coordinating with your guild members – clear communication and relationship-building are key to achieving shared goals. Strong interpersonal skills and effective communication are vital for efficient workflows.

- Cycle Counting & Reconciling: This is your daily grind – your “daily quests” that ensure data integrity. Efficient methods and a keen eye for discrepancies are crucial for maintaining an accurate inventory count.

Advanced Techniques: Leveling Up Your Game

- Demand Forecasting: Anticipating future needs is a crucial aspect of strategic inventory management. Think of it as predicting the enemy’s moves. Analyzing historical data and market trends is essential to optimize stock levels.

- Data Analysis: Beyond simply recording data, you need to interpret it. Think of it as studying battle logs – identifying patterns and trends can reveal areas for improvement in your processes. Proficiency in spreadsheets and data visualization tools is invaluable.

- Supply Chain Optimization: Understand the entire flow of goods – from supplier to customer. Think of it as mastering the game’s economy. Identifying bottlenecks and improving processes throughout the supply chain enhances overall efficiency.

- Trucking/Logistics Understanding (Depending on the role): Knowledge of transportation methods and logistics is essential, especially in roles that heavily involve shipping and receiving. This is understanding the game’s transportation system.

- Purchasing (Depending on the role): Negotiating with suppliers and managing procurement processes is crucial in many inventory roles. This is akin to strategic resource acquisition in the game.

Key Performance Indicators (KPIs): Measuring Your Success

Track your performance against metrics such as inventory accuracy, order fulfillment rate, and stock turnover. These are your “end-game achievements” – the ultimate measure of your effectiveness.

How to manage inventory in Excel?

Alright gamers, let’s level up your inventory management! Forget those clunky systems, we’re building a spreadsheet beast in Excel (or Google Sheets – same diff). First, create a new spreadsheet. Think of it as your inventory dungeon. Now, add columns. Don’t just slap in product names; we need power-ups! Think “Product ID” (unique identifier, crucial!), “Product Name,” “Category” (swords, potions, armor – you get it), “Unit Cost,” “Selling Price” (profit margin, baby!), “Quantity on Hand,” “Reorder Point” (don’t let your stock hit zero!), and “Supplier.” That’s your core stat sheet.

Next, add your products. Each row is an item. Populate those columns. This is where the grind begins, but it’s worth it for the loot. Remember, accurate data is your XP. Sloppy entries lead to game overs.

Now the fun part: adjust quantities. Every sale? Update the “Quantity on Hand.” This is where you track your progress, see your gains, and realize what’s selling like hotcakes (or, you know, powerful swords). Use formulas! Calculate total value, profit, and low-stock warnings. Excel’s got the tools; you gotta use ’em. This ain’t no casual playthrough. We’re going for the platinum trophy here. Think of conditional formatting for visual alerts – red for low stock, green for plenty. Seriously, it makes a huge difference.

Pro-tip: Consider using a separate sheet for suppliers, linking it to your main inventory sheet using VLOOKUP or INDEX/MATCH. This makes ordering new stock a breeze. You can also use pivot tables for advanced analysis – see which items are your best sellers or which categories need more attention. Don’t sleep on those advanced features! They’re your secret weapons.

What are the 4 types of inventory?

Alright guys, so you wanna level up your inventory management game? First, you gotta know your inventory types. Think of it like this – it’s your loot, but categorized for maximum efficiency.

There are four main types:

- Raw Materials: This is your basic loot – the unprocessed stuff you need to craft higher-level items. Think ore for your sword, wood for your bow, or the components to build your next crazy gadget.

- Work-in-Process (WIP): This is your partially crafted loot. It’s not quite ready to sell, but it’s getting there. Imagine that half-finished sword, or the chassis of your awesome vehicle, still needing a few parts. Managing WIP is crucial, or you’ll end up with a huge backlog of unfinished quests.

- Finished Goods: Your fully crafted, ready-to-sell items! These are the swords, bows, vehicles, gadgets – your fully functional, sellable loot. Tracking these is key to knowing your profit margins and what’s selling hot.

- Maintenance, Repair, and Overhaul (MRO): This is like your repair kits and upgrade parts – the stuff you need to keep your production line running smoothly. Think of it as the oil for your engine, or the potions to heal your warrior. Neglecting MRO is a recipe for downtime – and lost loot.

Knowing these types lets you optimize your inventory, preventing overstocking on useless items, identifying bottlenecks in your production chain, and making sure you always have the resources you need. This is crucial for maximizing your profits and minimizing losses. Think of it as strategic resource management – the key to ultimate success in the game of business!

What are the ABCS of inventory?

Yo, what’s up, inventory ninjas? So you wanna know the ABCs of inventory management? Think of it like this: it’s all about prioritizing your loot.

ABC analysis is your secret weapon. We’re talking about categorizing your items based on their value and demand. It’s not just about the *number* of items, it’s about their *impact* on your bottom line.

- A-items: These are your legendary items – high-value, high-demand clothing. Think limited edition sneakers or that killer designer dress. These are your cash cows; you gotta keep ’em stocked and secure.

- B-items: Your trusty sidekick items. They’re moderately valuable and in moderate demand. These are your reliable workhorses. Keep an eye on them, but you don’t need to be hyper-vigilant.

- C-items: Your bulk items – low value, high quantity. Think basic tees or socks. You need these, but they’re less critical to your overall success. Just make sure you have enough.

Why is this so crucial? Because you don’t want to waste precious time micromanaging your low-value items. Focus your energy on the A-items – that’s where the real profit’s at. Think of it like leveling up your business. You wouldn’t spend all your time grinding for common items when you could be farming legendary loot, right?

- Tight control on A-items: Accurate forecasting, robust security, and super-efficient ordering are KEY here.

- Moderate control on B-items: Regular stock checks and a bit of forecasting are enough.

- Loose control on C-items: Simple stock checks and bulk ordering will do the trick.

Mastering ABC analysis is like getting a cheat code for your inventory. It’s about strategic resource allocation, maximizing profits, and minimizing headaches. Level up your inventory game!

Is inventory management a hard skill?

Inventory management? Definitely a hard skill, folks! We’re not just talking about casually stacking boxes. Think deep dives into inventory control systems – we’re talking ERP systems, WMS, even custom-built solutions. Mastering these is crucial for accurate tracking, forecasting demand, and minimizing waste. Then there’s the logistics side – managing the entire distribution process, from sourcing to delivery. Understanding lead times, optimizing routes, and coordinating with suppliers – it’s a whole ecosystem. And finally, the data analysis bit. You’re not just counting stock; you’re analyzing trends, identifying slow-moving items, and predicting future needs using sophisticated tools and techniques like ABC analysis and forecasting models. Proficiency in these areas is what separates the average stock clerk from a true inventory management ninja.

How to become a good inventory manager?

Mastering inventory management isn’t just about tracking widgets; it’s about orchestrating the symphony of supply and demand. Accuracy is your bedrock. Think meticulous record-keeping, not just for the sake of it, but to fuel your predictive powers. Imagine a world where you know exactly when that crucial component will run low, before it even happens – that’s the power of precise data.

Communication is your weapon. Suppliers aren’t just vendors; they’re allies in your quest for optimal inventory levels. Foster strong relationships, built on clear communication and mutual understanding. Similarly, empower your team. Clear, concise directives and open feedback loops are essential. Think of your team as an extension of your inventory management brain, constantly relaying crucial data.

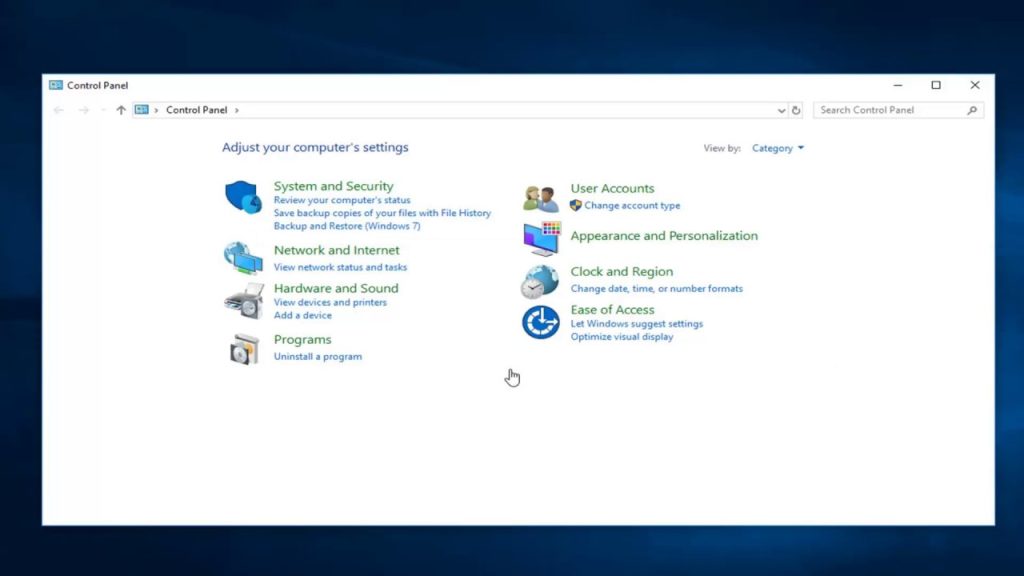

Software is your strategic advantage. Forget pen and paper; master the tools that automate processes, providing you with real-time insights. Become fluent in your inventory management software – learn its nuances, leverage its features to the max. This isn’t just about using the software; it’s about understanding how it integrates with the whole supply chain ecosystem.

Analytical prowess is your superpower. Forecasting isn’t guesswork; it’s a science powered by data analysis. Dive deep into trends, identify patterns, anticipate fluctuations. Mastering this allows you to proactively address potential shortages or surpluses. Problem-solving isn’t just about fixing errors; it’s about preventing them in the first place. By anticipating and mitigating potential issues, you become a true inventory management maestro.

What is the ABC of inventory management techniques?

Alright guys, so you’re asking about the ABCs of inventory management? It’s all about the ABC Analysis. Think of it like this: you’ve got your inventory, right? It’s not all created equal. ABC Analysis categorizes everything into three groups based on value and importance.

A items are your VIPs – high-value, high-impact stuff. These are the items that make or break your business. Think of your most expensive and critical components. These need the most scrutiny – tight control over stock levels, regular monitoring, maybe even dedicated storage and security. You need to know exactly where these are, at all times.

B items are the middle ground – moderate value and importance. They’re important, sure, but not as crucial as the A items. You’ll still want to keep a close eye on them, but the level of attention is less intense. Think of these as your reliable workhorses.

C items are your bulk items – low value, low impact. These are the things you usually buy in large quantities, and a little extra or a little less doesn’t significantly affect your bottom line. These usually require the simplest inventory management techniques – a basic stock check now and then is usually enough.

The key takeaway? Don’t waste time micromanaging your C items. Focus your energy on the A items, making sure you don’t run out and that you’re not overstocked. The B items fall somewhere in between, allowing you to optimize your resources effectively. It’s about prioritizing where your efforts yield the best results. This analysis helps you allocate resources intelligently, reducing costs and improving efficiency.

Pro-tip: Regularly review your ABC classifications. Market changes and seasonal demands can shift your items between categories, so you need to adapt your strategy accordingly.

What is the golden rule for inventory?

Alright gamers, let’s talk inventory management, the ultimate boss battle in any business. The golden rule? It’s all about that sweet spot – enough stock to keep your customers happy without drowning in excess inventory. Think of it like this:

Too little stock, and you’re getting those dreaded “out of stock” messages. That’s a major hit to your reputation and profits. It’s game over for sales potential.

Too much stock? That’s like hoarding useless loot in your inventory – it ties up your capital, takes up valuable space, and can even lead to items expiring or becoming obsolete. Think of it as carrying around tons of useless potions in a dungeon crawl – slows you down and weighs you down.

So how do you win this battle? Here’s the strategy:

- Accurate Forecasting: Predict demand like a pro. Use historical data, market trends, and even magical crystal balls (just kidding… mostly). The better your prediction, the closer you get to the perfect balance.

- Efficient Ordering: Don’t just bulk buy everything! Use smart ordering systems to replenish stock as needed. Just-in-time inventory is your best friend. Think of it as meticulously managing your mana pool.

- Regular Stock Audits: Keep tabs on what you’ve got. Regular stocktaking is like clearing out your inventory screen – gets rid of unnecessary clutter and helps with accurate accounting.

- Inventory Management Software: Level up your game with software. It automates tracking, ordering, and forecasting. It’s your trusty sidekick in this challenging raid.

Mastering inventory is a marathon, not a sprint. Consistent monitoring and adjustments are key. But once you nail it, you’ll be reaping those rewards – increased profits, happy customers, and a sense of accomplishment that’s truly epic.

How can inventory be controlled?

Alright folks, let’s dive into inventory control – think of it as a boss battle in your business RPG. First, prioritize location and accessibility. Bad placement is like searching for a key item in a ridiculously cluttered dungeon – a total waste of time. Think strategic placement, like clustering frequently used items near your “workstation”.

Next, establish the floor and layout arrangement. This is your dungeon design – optimize the flow! Poor layout equals wasted movement and time, similar to getting lost in a maze.

Get rid of unneeded stock. That’s your inventory cleanup – junk in your bag slows you down. Regular purges prevent clutter and save storage space, like selling unwanted loot to a merchant.

Set a cycle count schedule. This is your automated save system; regular checks prevent inventory discrepancies from becoming game-breaking. A set schedule keeps you on track.

Check stock quickly after delivery – this is like inspecting your newly acquired equipment; verifying quantity and condition prevents frustrating bugs later.

Label all products. Think of it as equipping items with their descriptions – clarity prevents errors, and it’s essential for quick identification, like instantly recognizing a powerful weapon.

Keep an eye on expiration dates. Avoid the dreaded “item decayed” message! Managing expiry is crucial, it’s like tracking the durability of your gear – essential for keeping your inventory effective.

Finally, make sure you’re keeping track of your inventory. Use a system – a spreadsheet, dedicated software, whatever works for you. This is your quest log – keeping track of what you have and what you need is fundamental. Think of it as your character sheet – essential for your overall success.

What are the 3 basic golden rules?

Let’s break down the fundamental accounting rules, but with a pro gamer’s mindset. Think of your balance sheet as your in-game economy:

1) Debit what comes in – credit what goes out: This is like managing your in-game resources. When you earn gold (debit), it increases your total. When you buy an item (credit), it reduces your gold. Consistency here is key to avoiding frustrating losses – just like maintaining your KDA (kills, deaths, assists).

2) Credit the giver and Debit the receiver: Imagine trading items with another player. The person giving you an item credits their inventory, while you, the receiver, debit yours. It’s about tracking the flow of assets—the exact same concept applies to transactions with suppliers and customers.

3) Credit all income and debit all expenses: Your tournament winnings are credited (income), while your coaching fees are debited (expenses). Proper tracking here is essential for calculating your net worth – crucial to understanding your overall performance and financial strategy. Think of it as optimizing your build: smart financial decisions lead to greater success.

What is the formula for inventory?

Alright viewers, let’s crack this inventory formula. It’s a bit like a puzzle, but trust me, once you get the hang of it, it’s a breeze. The core equation is: Beginning Inventory = Sales (COGS) + Ending Inventory – Purchases.

Now, let’s break down the boss fight, I mean, the variables. Sales (COGS), or Cost of Goods Sold, is how much it *actually* cost you to make or buy the stuff you sold. Think of it as your expenditure directly linked to sales. Don’t confuse this with revenue; it’s your *cost*, not your profit.

Next, Ending Inventory is simply what you have left over at the end of the accounting period – the unsold items. This is your remaining stock.

Finally, Purchases represent the value of all new inventory added during that period. This is straightforward – everything you bought or produced to add to your stock.

So, picture this: You start with a certain amount of inventory (Beginning Inventory). You sell some (Sales/COGS), then add more (Purchases). What’s left is your Ending Inventory. The formula is essentially reverse-engineering this whole process to find out your initial stock.

Pro-tip: Accurate inventory management is crucial. Think of it as your in-game resources; a proper count ensures you don’t run out, and prevents nasty surprises during audits (aka. game over).

Another thing to keep in mind is the various inventory valuation methods (FIFO, LIFO, weighted average). These affect how you calculate COGS and ending inventory, leading to different results. But that’s a boss battle for another day!

How do you keep track of inventory?

Alright folks, so you wanna know how to keep track of your in-game inventory, huh? Think of it like managing your quest log – you gotta stay organized, especially as your loot piles up. For those starting out, small-scale operations, it’s like a solo run. A simple spreadsheet – think of it as your trusty notebook – or a manual ledger, that’s your handwritten scroll of inventory, will do the trick. Just gotta be diligent with those entries.

But hey, let’s say you’re raiding dungeons with a party now. Your business is booming, you’re getting serious loot. You can’t rely on pen and paper anymore. It’s time to upgrade your inventory management system.

- Inventory Management Software: This is like finding that epic legendary weapon that makes all the difference. It’s powerful, efficient, and lets you track everything without losing your sanity. Tons of options out there, find one that fits your playstyle (business needs). Some even come with cloud saving!

- Barcode Scanners: These are like your trusty sidekick. Quick, accurate, and helps you identify items instantly. No more painstakingly typing in item names, saving you precious time.

- RFID Systems: Think of this as having magical eyes that can see through walls (and boxes!). This advanced tech tracks everything automatically. Great for large warehouses or complex inventory situations, but it’s a high-level investment.

- Automated Robots: This is endgame stuff. Only for the biggest businesses. Imagine automated systems sorting and moving your items for you – it’s the ultimate power play. Requires significant upfront investment, of course.

Choose your path wisely, based on your current level (business size) and future goals. Starting small is fine, but always plan for upgrades as you progress. Don’t get overwhelmed by the options – find a system that works for you and stick with it. You’ll be an inventory management master in no time!

Is Excel good for inventory management?

Listen up, rookie. Inventory management in Excel? It’s not exactly a cakewalk, but it’s a damn sight better than doing it by hand. Think of it as your first dungeon crawl – challenging, but doable with the right gear. A pre-made template? That’s your starting kit, a decent weapon and some basic potions. But to become a true inventory master, you’ll need to customize it. This is where the real grind begins.

Forget simple lists. We’re talking about powerful formulas, the equivalent of legendary spells. VLOOKUP lets you cross-reference data like a boss, instantly finding the price of an item. SUMIF? Your trusty sidekick for calculating totals based on specific criteria. Pivot Tables? That’s your endgame boss-killer, allowing you to analyze your inventory data from every angle, uncovering hidden patterns and opportunities. Learn to wield them and watch your inventory efficiency skyrocket.

Don’t underestimate the power of macros. These are your custom-crafted magical artifacts. Automate repetitive tasks like updating stock levels or generating reports – freeing up precious time to conquer other challenges in your business. And for the ultimate endgame? Integrate your Excel spreadsheet with other tools, creating a synergistic network that’ll leave even the most hardened spreadsheet warriors awestruck. This is inventory management on legendary difficulty, but with the right skills and a little elbow grease, you can conquer it.

What is the 80 20 rule of ABC analysis?

Alright folks, so you’re asking about the 80/20 rule in ABC analysis? Think of it like this: you’re raiding a dungeon, right? You spend 80% of your time fighting minor goblins, collecting measly copper coins and rusty swords. But that remaining 20%? That’s where the legendary dragon’s hoard is, the epic loot that makes the whole run worthwhile. That’s the Pareto Principle in action.

ABC analysis is all about prioritizing. It’s a strategic inventory management technique, but the core concept applies everywhere. We’re sorting items into three categories based on their value or importance:

- A-items: That 20% of items representing about 80% of your total value. In our dungeon raid analogy, this is the dragon’s hoard. Focus your attention here. Tight inventory control, frequent monitoring, and superior security are crucial. Don’t lose those gems!

- B-items: The middle ground. Moderate value, requiring less intense scrutiny. Maybe some enchanted armor or a decent amount of gold – worth having, but not as critical as the dragon’s treasure.

- C-items: The remaining 80% of items, contributing only about 20% of the total value. Think common potions, basic weapons, or that pile of goblin teeth you keep meaning to sell. Less frequent monitoring is fine; you’ll keep an eye on them, but they aren’t your primary concern. Bulk buying, automation, and simpler tracking systems might be more efficient here.

So, how’s this useful? It helps you allocate your resources effectively. You wouldn’t spend all your time polishing those goblin teeth, would you? Similarly, ABC analysis lets you focus on the high-value items (A-items) – maximizing your efficiency and profit (or epic loot!), and managing the rest accordingly. It’s a game changer for optimizing anything, from inventory to project management.

Key takeaway: Identify your A-items – your ‘dragons’ – and prioritize them above all else. Mastering this strategy is a serious upgrade to your overall performance in any situation.

What is the ABC rule of inventory?

So, the ABC analysis for inventory? It’s all about prioritizing your stock. You’re essentially categorizing your SKUs based on their value – usually sales volume or profitability. Think of it like this:

- Class A: These are your superstars. They’re your top performers, driving the majority of your revenue. Focus heavily on these – accurate forecasting, minimal stockouts, and top-notch supply chain management are crucial here. We’re talking about your bestsellers, the items that keep the lights on.

- Class B: These are your solid performers, a nice middle ground. They contribute significantly, but not as much as Class A. You’ll still want to monitor them closely, but your level of attention can be a bit less intense.

- Class C: Your bulk items. They make up a large portion of your SKUs, but individually contribute less to overall revenue. Think of them as the supporting cast. Focus here should be on efficient management to avoid excessive holding costs. Simple, streamlined processes are key.

Now, the three-tier system (A, B, C) is a great starting point, but you can absolutely refine it. Some businesses use more granular classifications – A through F, for instance, offering a more nuanced view of their inventory. The more categories you have, the more precise your management can be, but it also means more work in classifying and tracking.

Important Note: The percentages allocated to each class can vary wildly depending on your business. There’s no magic ratio. You need to analyze your own data to determine the optimal allocation for your business. Regularly reviewing and adjusting these classifications is key to keeping your inventory strategy sharp.

- Analyze your sales data and profitability.

- Identify your top-performing SKUs.

- Categorize your SKUs into A, B, and C classes (or more).

- Develop tailored inventory management strategies for each class.

- Regularly review and adjust your classifications based on ongoing sales trends.

How do you calculate how much inventory you need?

That formula, while a starting point, is drastically oversimplified and unsuitable for most businesses. It relies on perfectly predictable consumption and lead times – a rare occurrence. Real-world inventory management requires a more nuanced approach.

The formula “minimum inventory level = reorder point – [normal consumption × normal delivery time]” only addresses safety stock inadequately. A more robust calculation incorporates safety stock, which accounts for fluctuations in demand and lead times. This safety stock should be determined by analyzing historical data to assess the standard deviation of demand and lead time. Consider using a service level calculation to define an acceptable risk of stockouts. Higher service levels require larger safety stocks.

Furthermore, this basic formula ignores factors like: seasonal demand peaks, promotional activities, lead time variability, potential supplier disruptions, and the cost of holding inventory (storage, obsolescence, insurance, etc.). Ignoring these leads to either costly overstocking or crippling stockouts.

Sophisticated inventory management techniques like the Economic Order Quantity (EOQ) model, which balances ordering costs against holding costs, provide a more comprehensive solution. EOQ, however, still assumes consistent demand and lead times. For businesses with highly variable demand, consider employing forecasting techniques, such as exponential smoothing or ARIMA modeling, to predict future demand more accurately. Regularly reviewing and updating your inventory forecasts and parameters is vital to adapt to changing market conditions.

Ultimately, effective inventory management involves a combination of quantitative analysis (using formulas and data) and qualitative judgment (considering market trends and business intuition). Relying solely on a simplistic formula is a recipe for inefficient inventory levels.